Copyright © Guangdong Lvzhidao Metal Materials Co., Ltd. All Rights Reserved. Site Map

- +86-13556798819

- laigp@dglzd.com

- Room 302, Building 1, No. 45 Shipai Avenue West, Shipai Town, Dongguan City, Guangdong Province

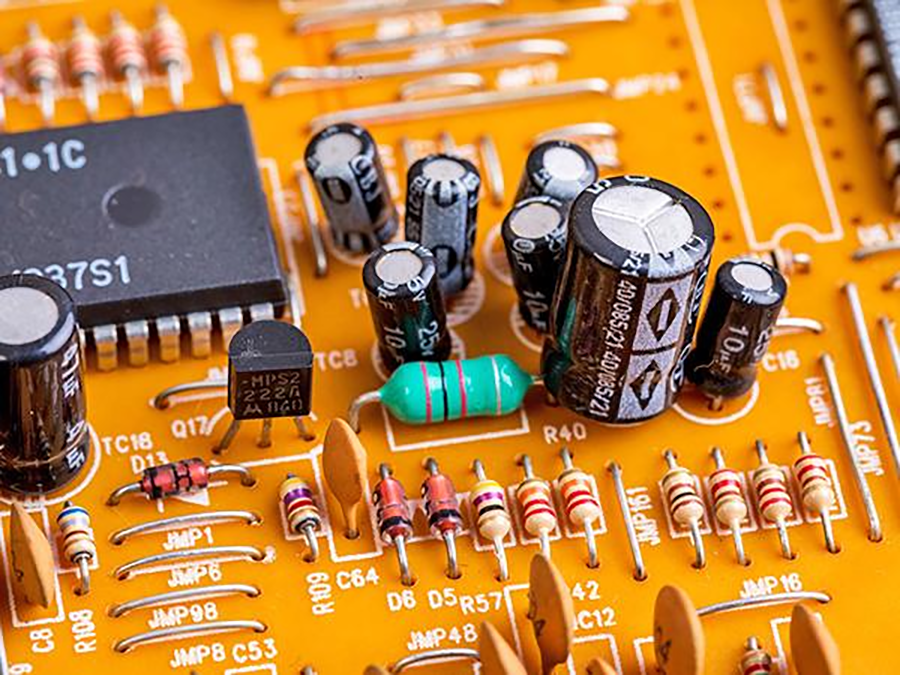

SMT (surface mounting technology) components play a crucial role in electronic products, and their failures may have a serious impact on the function, performance and reliability of electronic products. In order to reduce the impact of SMT component failure on electronic products, we can start from the following aspects:

1. Select high-quality components

Procurement Channel: Components should be purchased from reputable suppliers to ensure the initial quality of components.

Quality Testing: During the procurement process, strict quality inspection should be carried out on components, including appearance inspection, performance testing, etc., to ensure that components comply with relevant standards and requirements.

2. Strictly control the production environment and process parameters

Production Environment: Make the production environment clean and suitable temperature and humidity to reduce the impact of environmental factors on components. For example, use anti-static equipment and workbenches to reasonably control the humidity and temperature of the working environment to suppress the generation of static electricity.

Process parameters: During the SMT patch processing process, strictly control the welding parameters, such as temperature, time, solder quantity, etc., to ensure solder quality and stability. At the same time, the temperature curve of the reflow soldering furnace is optimized to make it within the optimal temperature range to avoid welding problems caused by temperature abnormalities.

3. Strengthen equipment maintenance and calibration

Equipment maintenance: Regularly maintain and maintain SMT equipment, including cleaning, lubrication, inspection, etc., to ensure the normal operation and accuracy of the equipment.

Equipment calibration: Calibrate the equipment regularly to ensure the accuracy and accuracy of the equipment and avoid component failures caused by equipment errors.

4. Improve operator skills and quality awareness

Skill training: Conduct regular skills training for operators, including training in equipment operation, process flow, quality inspection, etc., to improve their operating proficiency and quality awareness.

Quality Monitoring: Establish a strict quality monitoring mechanism to monitor and record key parameters and quality indicators in the production process in real time, and detect and deal with abnormalities in a timely manner.

5. Establish a fault analysis and processing mechanism

Fault Analysis: For SMT component failures that have occurred, conduct timely failure analysis to find out the root cause and cause of the problem.

Improvement measures: According to the results of the fault analysis, corresponding improvement measures, such as optimizing the process flow, replacing component suppliers, etc., to avoid similar failures from happening again.

6. Strengthen anti-static measures

Antistatic packaging: When storing and transporting components, use antistatic packaging materials to reduce the impact of components by static electricity.

Electrostatic discharge test: Electrostatic discharge test on key equipment and components on the production line to ensure that the antistatic performance of the equipment or components meets the standard requirements.

To sum up, reducing the impact of SMT component failures on electronic products requires starting from multiple aspects, including selecting high-quality components, strictly controlling production environment and process parameters, strengthening equipment maintenance and calibration, improving operator skills and quality awareness, establishing fault analysis and handling mechanisms, and strengthening anti-static measures. The implementation of these measures will help improve the quality and stability of electronic products, improve user experience and satisfaction.